The Single Strategy To Use For Sheroz Earthworks

The Single Strategy To Use For Sheroz Earthworks

Blog Article

How Sheroz Earthworks can Save You Time, Stress, and Money.

Table of Contents9 Easy Facts About Sheroz Earthworks ExplainedGet This Report about Sheroz EarthworksTop Guidelines Of Sheroz EarthworksThe smart Trick of Sheroz Earthworks That Nobody is Discussing

There are numerous companies that produce quality equipment control systems, and Trimble device control is one of the industry leaders. We can produce 3D apply for devices utilizing Trimble maker control systems as well as Topcon, AGTEK and all other significant device control systems. topcon. Typically, our turnaround time has to do with five days, relying on the complexity and size of your jobJust head to the Machine Control tab or the Send Out United States Work (https://lwccareers.lindsey.edu/profiles/5240299-floyd-overbeck) tab on our site and send your project

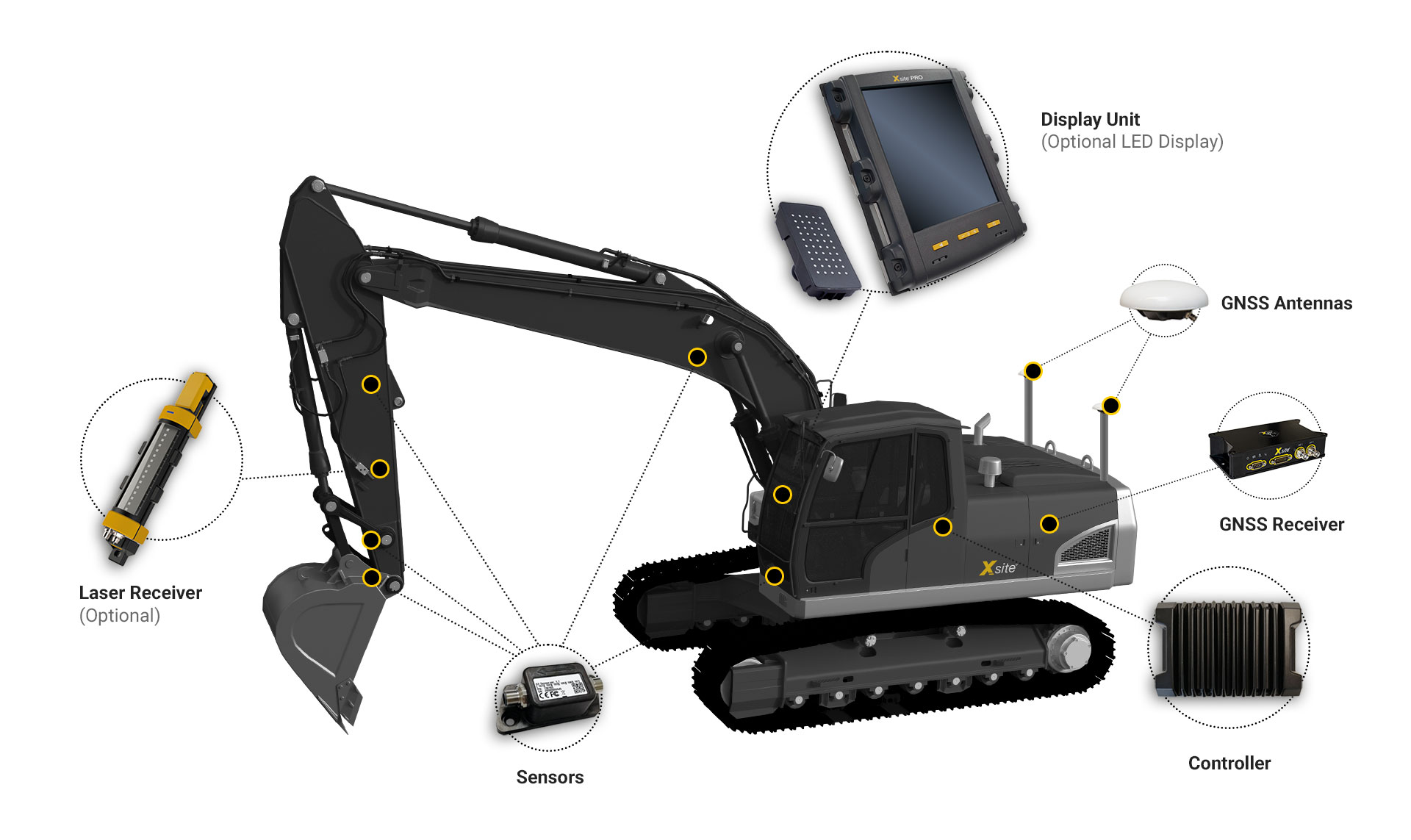

With the help of the maker control system the driver will locate it easy to deal with any type of job. The clear 8,4 touch display with intutive interface makes it possible for the operator to easily check the difference in the altitude of the bucket's blade and the target surface area. Various functions of the Xsite PRO 3D are developed as simple to make use of as possible.

With the current technology boom taking the globe by storm, the building sector has actually gone through numerous adjustments and renovations in current times. Among the tech technologies leading this transformation is machine control modern technology - trimble parts. Machine control innovation, which has actually been spreading anywhere, includes using satellites and 3D designs that make it possible to assess a machine's specific place in the world and contrast this position with a desired layout surface area

The Ultimate Guide To Sheroz Earthworks

Throughout a construction task, there are many times when individuals have to make essential decisions to ensure that points stay on track in regards to time, efficiency, and financial elements. With maker control modern technology, you can make important decisions based upon concrete data as opposed to fallible traditional techniques or differing operator abilities and experience.

Numerous 3D general practitioner positioning vendors have actually shown time and time once more that implementing device control modern technology will certainly help bring your operating expenses down by boosting performance on your job sites. Exactly how does this dazzling modern technology make that feasible? The following are a few of the primary methods that equipment control modern technology enhances task site efficiency: It can be extremely aggravating (and expensive) to deal with substantial downtime since you need to execute a rework.

Additionally, less reworks will certainly lead to a lot more reliable job conclusion and faster turn-around times. One more manner in which maker control innovation can assist enhance efficiency is by boosting the predictability of various tasks when it involves variables such as needed time and products. https://hubpages.com/@sherozau. When you can predict such variables, it is possible to allot equipment and employees, and it is also a lot more practical to maintain material expenses to a minimum

Sheroz Earthworks for Beginners

On the other hand, if you are not able to precisely analyze just how click now to allocate time, materials, and workers for jobs, it might cause you needing to invest added time and sources to correct miscalculations. In addition to working a lot more effectively, equipment control modern technology permits you to function smarter. This innovation can educate a specialist to reduce down their use of three dozers on a particular job site to simply 2, releasing up the third to another job site.

Several contractors alloted a substantial quantity of time and money for a project to dedicate to re-staking throughout the work for various factors, such as transforming styles or stakes obtaining relocated or run over. Nevertheless, with device control technology, the data factors stay the same unless the design adjustments, so you do not need to fret about dealing with this.

Equipment control innovation makes it less complex for inexperienced employees to handle their service building job sites. Since there is much less space for mistakes, there is less of a knowing contour for new employees. It will certainly also be less complicated to draw in the focus of new, more youthful employees, hence streamlining working with periods.

The ideal way to ensure you can maximize the positive effect on your business is to select a General practitioner champ who can function directly with the innovation vendor. We think all business should have the possibility to try brand-new innovation, so we established an 18 month Rent-To-Own program that allows you to realize the financial advantages of the system while you pay for it.

They are specialists on Hemisphere GradeMetrix, Topcon, and Trimble systems. Whether you require assist with setup, calibration, data management, or operator user interface training, we would certainly enjoy to supply remote or onsite support and walk you through easy-to-follow options. Our utmost goal is to make carrying out 3D innovation into your company simple and painless.

Our heavy devices experts would likewise be delighted to aid direct you in the appropriate direction pertaining to such matters (trimble tripod parts).

Report this page